Walker Multi Anvil

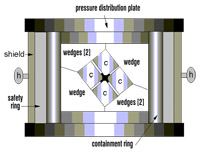

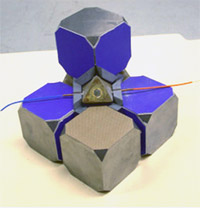

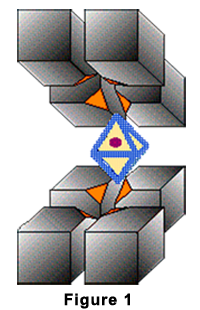

Multi-anvil systems can achieve pressures of 250 kbar and temperatures to 3000°C. The sample is placed in a hole (purple colored area figure A) within a pressure medium shaped into an octahedron and fabricated from alumina, pyrophyllite or some other ceramic material, as shown in the opened view to the left. The faces of the octahedron seat against the truncated corners (orange colored area figure A) of eight tungsten carbide (WC) cubic anvils. The cubes in turn are nested within split-spherical or cylindrical seats fabricated from tool steel and sectioned into segments that fit into a massively supported guide-block. Until recently, these systems were heavy and cumbersome, requiring very large presses and a considerable effort to operate them up to their design pressures.

Multi-anvil systems can achieve pressures of 250 kbar and temperatures to 3000°C. The sample is placed in a hole (purple colored area figure A) within a pressure medium shaped into an octahedron and fabricated from alumina, pyrophyllite or some other ceramic material, as shown in the opened view to the left. The faces of the octahedron seat against the truncated corners (orange colored area figure A) of eight tungsten carbide (WC) cubic anvils. The cubes in turn are nested within split-spherical or cylindrical seats fabricated from tool steel and sectioned into segments that fit into a massively supported guide-block. Until recently, these systems were heavy and cumbersome, requiring very large presses and a considerable effort to operate them up to their design pressures.

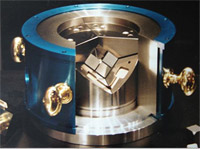

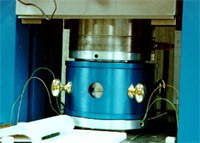

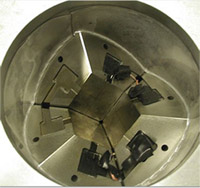

The main obstacles to research on bulk materials at pressures of 50-250 kbar have been eliminated as a result of simplifications to multi-anvil design and technique recently introduced by Dr. David Walker at the Lamont-Doherty Earth Observatory of Columbia University. As illustrated in the schematic cross-section below, and in the photographs of the Walker module, a cylindrical cluster of wedges is used to seat the tungsten carbide anvils (C). The wedges are loose and free to float within their supporting ring. Massive support of the cluster is not used; rather, the elastic strain during loading is taken up directly by the supporting ring.

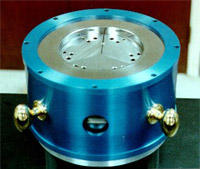

Module with upper pressure plate removed, showing the top cluster of three cylindrical wedges installed over the WC cubes. Knobs mounted on outer shield permit easy maneuvering for positioning of the module in the press. Port between knobs provides access for strain gauges.

Link to The Dynamic Earth at the Smithsonian National Museum of History where a Rockland Research Walker Multi-Anvil is featured.

Illustration of the internal configuration of the Walker Multi-Anvil module (this unit is on display at the Smithsonian Institution's Janet Annenberg Hooker Hall of Geology, Gems and Minerals at the National Museum of Natural History.

Link to the High Pressure Laboratory at the Smithsonian National Museum of History

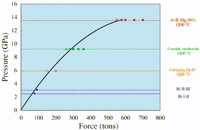

This graph shows the pressure calibration for the 14/8 (ram force vs. the pressure of "fixed" transitions). The Walker module is used for achieving pressures up to 25 GPa. In this device, six anvil "wedges" press on 8 cubes which in turn press on an octahedra press medium. The press is calibrated using a variety of sample assemblies, using both castable ceramic and semi-sintered ceramic pressure media. This configuration is used at Dr. Paul Asimow's lab at CalTech. The 14/8 ass'y is configured as follows:

-

14 mm edge length octahedron made of semi-sintered MgO plus 5 wt% Cr2O3

-

Stepped LaCrO3 heater

-

Pyrophyllite gaskets with a cross section of 2.8 x 4.5 mm